ETP Installation

400+

Waste Water Treated Per Day

70 MLD

Inhouse Manufacturing

Yes

Mega Project

45 MLD ETP at L&T Ludhiana

Effluent Treatment Plant – ETP for Automobile Service Center

| Capacity (KLD/MLD) | 2 KLD up to 40 KLD |

| Treatment Technique | Physico-chemical, Aerobic, Anaerobic, Advanced oxidation, Electro-coagulation and Precipitation (ECP) |

| Inlet Flow Rate(m3/day or m3/hr) | 500 Litre Per Hour Up To 4000 Litre Per Hour |

| Water Source | Automobile Service Center Effluent |

| Automation Grade | Automatic |

| Operation & Maintenance Support | Yes |

| Industries We Servee | Automotive |

| Turnkey Project with Civil | Yes |

| Government Compliances & Approval | CTE & CTO ( Consent to Establish & Consent to Operate) |

Comprehensive Treatment : Addresses a wide range of contaminants, including biological pathogens and chemical pollutants.

Pathogen Removal : Ensures the removal of harmful pathogens to prevent the spread of infections.

Chemical Neutralization : Neutralizes hazardous chemicals and pharmaceutical residues present in medical wastewater.

Effluent Quality Monitoring : Continuous monitoring of effluent quality to ensure compliance with regulatory standards.

Emergency Response : Built-in protocols for handling emergencies and unexpected fluctuations in wastewater composition.

Resource Recovery : Opportunities for resource recovery, such as energy generation from biogas produced during treatment processes.

Customizable Solutions : Tailored to meet the specific needs and capacity requirements of hospitals and medical facilities.

Environmental Sustainability : Promotes environmental sustainability by reducing the environmental impact of hospital operations.

Cost-Effective Operation : Optimized processes to minimize operational costs while ensuring effective wastewater treatment.

Safety Protocols : Implementation of safety protocols to protect personnel and prevent accidents during operation and maintenance activities.

| Plant Name | Prices |

|---|---|

| Automobile | Approx Price : Rs. 100000 |

customer testimonials

I've been consistently impressed with the product quality and outstanding service support from Awetech , their support team has been incredibly responsive, knowledgeable, Customer centric.

Dealership - Maruti Suzuki , Nexa , Tata, JCB

Project Manager - Mr. Ajay Jha

Product - ETP , RO , WTP

Location - Delhi , NCR , Haryana

Awetech Works is a one stop solution for all our Water management needs like Water & waste water collection, treatment, distribution and state Pollution board consent.

Dealership - Jaquar , Ahmedabad .

Project GM - Mr. Ravi Srivastava.

Product - ETP , Water Softner , RO

Location - Ahmedabad

Team Awetech is Water Consultant and Solution provider for all of our automotive dealerships. Awetech is our answer Against the today’s Water management challenges and tough government compliances.

Dealership - Tata , Skoda, Mahindra ,Hyundai Surat , Vapi

Group CEO - Mr. Raj Nimbhorkar

Product - ETP

Location - Gujarat

Awetech Works is our trusted partner for Effluent treatment solution and Water treatment plants, which is situated across the country. Awetech is offering us Operation and Maintenance service at 6x premium auto service station at Delhi. We are delighted by there service support.

Dealership - Jeep , Volkswagen

Purchase Manager- Mr. Hemendra soni

Product - ETP

Location - Gujarat , Punjab , Delhi , West Bengal, Haryana

Unlike past, it is crucial to have a water pollution expert in company’s project team. Awetech’s expertise in Water treatment and Pollution board compliances has helped us in setting up and operate our Automotive dealerships smoothly and freely.

Dealership - Maruti

CEO - Mr. B.keshwan

Product - ETP

Location - Gujarat , Maharashtra

In our Maruti dealership we wash average 100 Cars per day by using the Recycled Water from Awetech ETP. The quality of treated water from ETP is excellent. Awetech’s expertise in water treatment has helped us to reduce our fresh water intake by 80%.

Dealership - Maruti

CEO - Mr. Hiren Trivedi

Product - ETP

Location - Gujarat

Awetech fully Automatic ETP is a great peace of mind. We just need to ensure that availability of chemicals at site rest everything is done automatically. Awetech has made water treatment easy, effective and economical. .

Dealership - Maruti

CEO - Mr. Hasan Ali i

Product - ETP

Location - Rajesthan

At Toyota we always believe in Sustainable growth. Awetech work has supper out suistainabkity initiative by offering is its Automatic ETP that requires very less electricity, Chemicals and Space for its operation. Also, the quality of treated water is absolutely in line with lates pollution board guidelines. .

Dealership - Toyota

CEO - Mr. Rakesh parihar

Product - ETP

Location - Bikaner, Rajesthan

Firstly, Awetech won our trust by upgrading all of our existing ETP to meet the latest pollution board guidelines and Also made them easy to use and Maintain. Then they supplied new system for our upcoming workshops. Now, awetech works is our first choice for every ETP project or water pollution solution.

Dealership - Hyundai , Mahindra BMW

Group CEO - Mr. STTICK BANERJEE

Product - ETP

Location - Gujarat

Absolutely! Here's a revised version:

"The product's superior quality exceeded expectations! Awetch Works provided prompt service support, fulfilling our diverse water treatment needs for all workshops across North India. They're our one-roof solution. Highly recommended!"

Dealership - Tata , Maruti Suzuki, NEXA , JCB

Project Manager - Mr. Ajay Jha

Product - ETP, RO, WTP

Location - Haryana , Delhi - NCR

"Awetech Works manages ETP, softeners, RO, and other water treatment equipment for our 17 automotive workshops in Punjab. Their expertise, customer-centric approach, and maintenance-free plant design make them our trusted partner."

Dealership - Hyundai , MG

MD - Mr. Luv Goyal ji

Product - ETP

Location - Punjab

"Awetech's in-house manufacturing enabled custom space solutions for water and wastewater management, tailored to our site requirements. Their design team understands auto service station needs, optimizing our washing area effectively. Awetech Works is our go-to expert for water treatment solutions in the automotive industry."

Dealership - Maruti Suzuki

Project GM- Mr. TC Pandey ji

Product - ETP , RO

Location - Delhi NCR

"Awetech Works provides economical and efficient effluent treatment solutions backed by a team of experts. The best part is their cost-effective annual maintenance plans, ensuring equipment health at minimal cost."

Dealership - Maruti Suzuki

Group CEO - Mr. Sehaj Shabad Goyal

Product - ETP

Location - J&K , Uttarakhand

Firstly, Awetech won our trust by upgrading all of our existing ETP to meet the latest pollution board guidelines and Also made them easy to use and Maintain. Then they supplied new system for our upcoming workshops. Now, awetech works is our first choice for every ETP project or water pollution solution.

Dealership - Hyundai , Mahindra BMW

Group CEO - Mr. STTICK BANERJEE

Product - ETP

Location - Jammu & Kashmir

Why Effluent Should Be Treated for Automobile Service Centers

1. Environmental Protection :

Untreated effluent from Automobile Service Centers can contain a variety of harmful pollutants, including oil, grease, heavy metals, and toxic chemicals. Discharging such contaminants directly into the environment can lead to soil and water contamination, posing serious risks to ecosystems and public health. By treating effluent before discharge, service centers minimize their environmental footprint and contribute to the preservation of natural resources and biodiversity.

2. Regulatory Compliance :

Automobile Service Centers are subject to stringent environmental regulations governing wastewater discharge. Compliance with these regulations, including obtaining necessary permits and adhering to discharge limits, is essential to avoid fines, penalties, and legal consequences. Implementing an effective effluent treatment system ensures that service centers meet regulatory requirements and demonstrate their commitment to environmental stewardship and corporate responsibility.

3. Protection of Water Resources :

Wastewater from Automobile Service Centers often contains pollutants that can contaminate water bodies, posing risks to aquatic life and human health. By treating effluent to remove harmful substances, service centers help safeguard freshwater resources, ensuring their availability for drinking, irrigation, and recreational purposes. Clean water is essential for sustaining life and supporting ecosystems, making effluent treatment a crucial aspect of water resource management.

4. Public Health and Safety :

Untreated effluent may contain pathogens and other microorganisms that can spread diseases and pose health hazards to employees, customers, and nearby communities. By treating effluent to disinfect and eliminate harmful bacteria, viruses, and parasites, service centers protect public health and safety, creating a healthier environment for all stakeholders. Additionally, reducing exposure to hazardous chemicals and pollutants minimizes the risk of occupational illnesses and accidents among service center personnel.

5. Corporate Reputation and Brand Imaget :

As environmental awareness grows among consumers and stakeholders, businesses are increasingly evaluated based on their environmental performance and sustainability practices. Implementing effective effluent treatment demonstrates a service center’s commitment to environmental protection, social responsibility, and ethical business practices. By prioritizing environmental stewardship, service centers enhance their corporate reputation, build trust with customers, and differentiate themselves in the marketplace.

6. Operational Efficiency and Cost Savings :

Efficient effluent treatment systems not only protect the environment but also improve operational efficiency and cost-effectiveness for Automobile Service Centers. By recovering valuable resources from treated wastewater, such as water, energy, and recyclable materials, service centers reduce their reliance on freshwater sources, lower utility costs, and minimize waste disposal expenses. Investing in effluent treatment infrastructure yields long-term benefits, including reduced operational risks and enhanced profitability.

7. In conclusion :

effluent treatment is a fundamental requirement for Automobile Service Centers, driven by environmental, regulatory, health, and business imperatives. By treating effluent effectively, service centers demonstrate their commitment to sustainable operations, protect natural resources, and uphold their responsibilities to society and future generations. Effluent treatment is not just a necessity—it’s a cornerstone of responsible business practices in the automotive service industry.

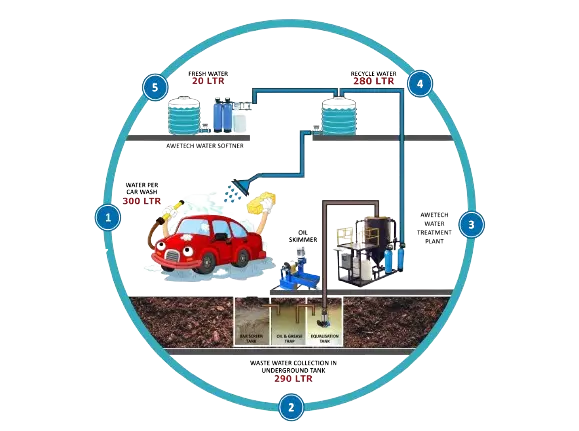

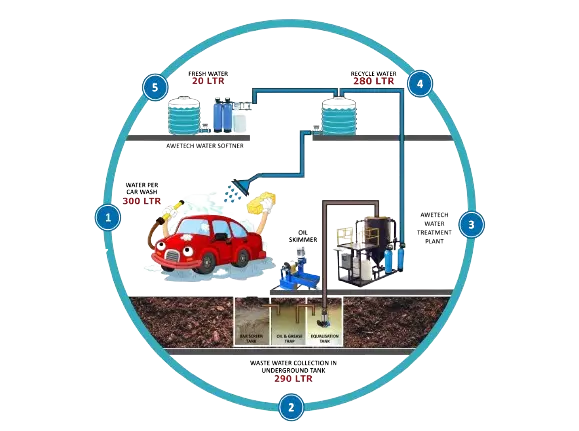

Effluent Treatment Plant (ETP) Process for Automobile Service Centers

Effluent Treatment Plant (ETP) Process for Automobile Service Centers :

At the heart of every Automobile Service Center lies an Effluent Treatment Plant (ETP), a sophisticated system meticulously designed to manage and treat wastewater generated during vehicle maintenance and servicing activities. The ETP employs a multi-stage treatment process, integrating various advanced techniques to ensure the efficient removal of contaminants and the production of environmentally safe effluent.

1. Collection and Pre-Treatment :

The process begins with the collection of wastewater from various sources within the service center, including vehicle washing areas, engine degreasing bays, and floor drains. This raw wastewater undergoes pre-treatment, where coarse solids such as oil, grease, and larger debris are removed through physical processes like screening and sedimentation.

2. Primary Treatment :

Following pre-treatment, the wastewater enters the primary treatment phase, where further separation of suspended solids takes place. In this stage, settling tanks facilitate the gravitational settling of heavier particles, while lighter materials like oil and grease are skimmed off the surface using mechanical skimmers. This step significantly reduces the organic load and turbidity of the wastewater.

3. Secondary Treatment :

After primary treatment, the wastewater undergoes secondary treatment to further break down organic pollutants through biological processes. Biological reactors such as activated sludge systems or aerobic digesters provide an ideal environment for the growth of microorganisms, which metabolize organic matter into simpler, less harmful compounds. This step effectively reduces the biochemical oxygen demand (BOD) and chemical oxygen demand (COD) of the effluent.

4. Tertiary Treatment :

In the tertiary treatment phase, the treated wastewater undergoes additional polishing to meet stringent discharge standards and ensure environmental compliance. Advanced techniques such as advanced oxidation processes (AOPs), membrane filtration, and chemical coagulation are employed to remove residual contaminants, including dissolved organic compounds, heavy metals, and pathogens. This stage enhances the quality of the effluent to meet regulatory requirements for safe discharge or potential reuse.

5. Disinfection and Final Effluent Discharge :

Before final discharge, the treated effluent undergoes disinfection to eliminate any remaining pathogens and ensure public health protection. Chlorination, ultraviolet (UV) irradiation, or ozonation may be utilized for this purpose, depending on the specific requirements and regulatory standards. Once treated and disinfected, the effluent is ready for safe discharge into receiving water bodies or, in some cases, for non-potable reuse applications such as landscape irrigation or industrial processes.

What Makes Us Different ?

Right Approch

Effluent Characteristics & Site Conditions Total cost of ownership over 10 Years of lifetime. Legal Compliance and desired treated water parameters.

Clean Commitment

On time project execution, periodic Operation and Maintenance training and perfect paperwork is our core strength. We consider our job is done when our client gets habitual of using the recycled water and gets all legal clearance from authorities.

Expert Solutions

Our team of experts creates the most economical, efficient and Maintenance free design that will be best for your application.

Frequently Asked Questions [FAQ]

An ETP for Automobile Service Centers is a specialized system designed to treat wastewater generated during vehicle maintenance and servicing activities.

Automobile Service Centers need an ETP to comply with environmental regulations, protect water resources, and ensure the safe disposal of wastewater.

Wastewater from Automobile Service Centers may contain oil, grease, heavy metals, suspended solids, detergents, and other chemicals used in vehicle maintenance processes.

An ETP treats wastewater through processes such as screening, sedimentation, biological treatment, chemical treatment, and disinfection to remove contaminants and produce clean effluent.

The capacity of an ETP for Automobile Service Centers typically ranges from 5 kiloliters per day (KLD) up to 1 million liters per day (MLD).

Yes, ETPs for Automobile Service Centers are often equipped with automated systems for efficient operation and monitoring of treatment processes.

The benefits of using an ETP include environmental compliance, protection of water resources, public health safety, and cost savings through resource recovery.

The maintenance frequency of an ETP depends on various factors such as the type of treatment processes, operating conditions, and regulatory requirements, but typically regular maintenance is recommended to ensure optimal performance.

Yes, treated effluent from an ETP can be reused for non-potable purposes such as vehicle washing, floor cleaning, and landscape irrigation, depending on local regulations and water quality standards.

Yes, Automobile Service Centers must obtain necessary permits and approvals from regulatory authorities for the construction and operation of their ETPs, including consent to establish (CTE) and consent to operate (CTO) certificates.

An ETP ensures compliance with environmental regulations through rigorous monitoring of effluent quality, adherence to discharge limits, and documentation of operational parameters as required by regulatory authorities.

Yes, ETPs are designed to handle a wide range of pollutants, including hazardous substances, through specialized treatment processes tailored to the specific characteristics of the wastewater.

Yes, the effluent discharged from an ETP is treated to meet regulatory standards and is environmentally safe for discharge into receiving water bodies or for reuse in approved applications.

The treatment time varies depending on factors such as flow rate, treatment capacity, and the complexity of the treatment processes, but typically, wastewater can be treated within a few hours to a day.

Yes, ETPs can be customized to meet the specific needs and operational constraints of Automobile Service Centers, including treatment capacity, space constraints, and regulatory requirements.

Sludge generated during the treatment process in an ETP is typically dewatered, stabilized, and disposed of in compliance with regulatory requirements or may be further treated for resource recovery.

An ETP contributes to resource recovery by recovering valuable resources such as water, energy, and recyclable materials from treated wastewater, thereby minimizing waste and reducing operational costs.

Common challenges in operating an ETP include fluctuating wastewater characteristics, equipment maintenance, compliance with regulatory standards, and ensuring the availability of skilled personnel.

Automobile Service Centers can ensure the long-term performance of their ETP by implementing regular maintenance schedules, conducting periodic performance evaluations, and investing in upgrades or improvements as needed.

Environmental consultants, engineering firms specializing in wastewater treatment, and equipment suppliers can provide assistance and support for the design, construction, and operation of ETPs for Automobile Service Centers.

Join Over +15,000 Happy Clients!

Salient Features

Concept to Commissioning

In-house team for Design. Engineering, Martufacturing, Execution and Service support gives full control over project ownership and quality

Experienced Team

Entire team possess average Industrial Experience of 7+ Year and have proven track record

Tailor Made Solutions

Our wide experience of solution design in multiple technologies enable us to choose technology that is most economical and efficient in long run.

Future Ready Products

Automation is the heart of every Awetech product. Our products performance can be monitored from remote location.

Life Cycle Management

We can take complete responsibility of product operation, maintenance, upgradation and comply latest pollution control board norms.

Comply Pollution Norms

Our design philosophy and documentation is in line with quidelines set by legal authorities. We provide support to take required approvals from pollution department

Awetech Works – The Leading Solution Provider of Effluent Treatment Plant (ETP) for Automobile Service Centers

- Industry-leading expertise in Effluent Treatment Plant processes for Automobile Service Centers.

- Tailored solutions designed to optimize efficiency, minimize environmental impact, and maximize cost-effectiveness.

- Commitment to sustainability through eco-friendly wastewater treatment processes.

- Customer-centric approach focused on delivering exceptional value and service.

- Ongoing support and expert guidance to ensure the success of every project.

Our Design Philosophy

Analyze & Inspect

"You cannot improve those things

which you can not evaluate”.

✓ Analyze Water or Waste Water

Parameters.

✓ Inspect site to check availability of

Space and utilities.

Understand Application

Our Sales professionals will take detailed note of your requirement & challenges. Factors like Future expansions, end use of Water and Water depletion rate plays a very important role product designing.

Technology Selection

" Wrong selection may save you some penny initially but take out far more during operation & maintenance”. Thus, technology selection considering the soaring prices of Electricity, Manpower, Space, chemical and consumables is essential.

Design & Manufacturing

As a standard procedure we first make to-the-scale 3D design of entire project with plumbing and other connections. After discussing it with client we starts manufacturing tailor made unit in our state-of-the-art facility.

Quality Inspection

Our Ever plant has to go through the stringent Quality test, where we test the strength of fabrication, Anti Corrosion coating, Dimensions, Water leakage test and product finishing.

ENQUIRE NOW

Served Locations

-

Uttar Pradesh (UP):

Kanpur; Lucknow; Ghaziabad; Agra; Varanasi & more… -

Madhya Pradesh (MP):

Indore; Bhopal; Jabalpur; Gwalior; Ujjain & more… -

Rajasthan:

Jaipur; Jodhpur; Kota; Bikaner; Ajmer & more… -

Jammu and Kashmir (J&K):

Srinagar; Jammu -

Gujarat:

Ahmedabad; Surat; Vadodara; Rajkot; Bhavnagar & more… -

Punjab:

Ludhiana; Amritsar; Jalandhar; Patiala; Bathinda & more… -

Delhi National Capital Region (NCR):

Delhi; Gurgaon (Gurugram); Noida; Faridabad; Ghaziabad & more… -

Maharashtra:

Mumbai; Pune; Nagpur; Thane; Nashik & more…